1953年創業、今治タオルの専門店IKEUCHI ORGANICのスタッフが、商品のご紹介や日々の洗濯、お手入れ、メンテンナンス方法などタオルのお役立ち情報のほか、オーガニックコットンの生産現場や今治本社工場での環境に配慮した取り組みなど、ものづくりの背景をコラムでご紹介しています。

Low Impact Dye, a dyeing method that considers people and nature

2022.12.19

Table of Contents

The dyeing process is the most energy-intensive part of the towel production process, and at IKEUCHI ORGANIC we dye towels based on the “Low Impact Dye” concept, which aims for maximum safety and the least environmental impact.

Dyeing factory treating wastewater that is clearer than ocean water

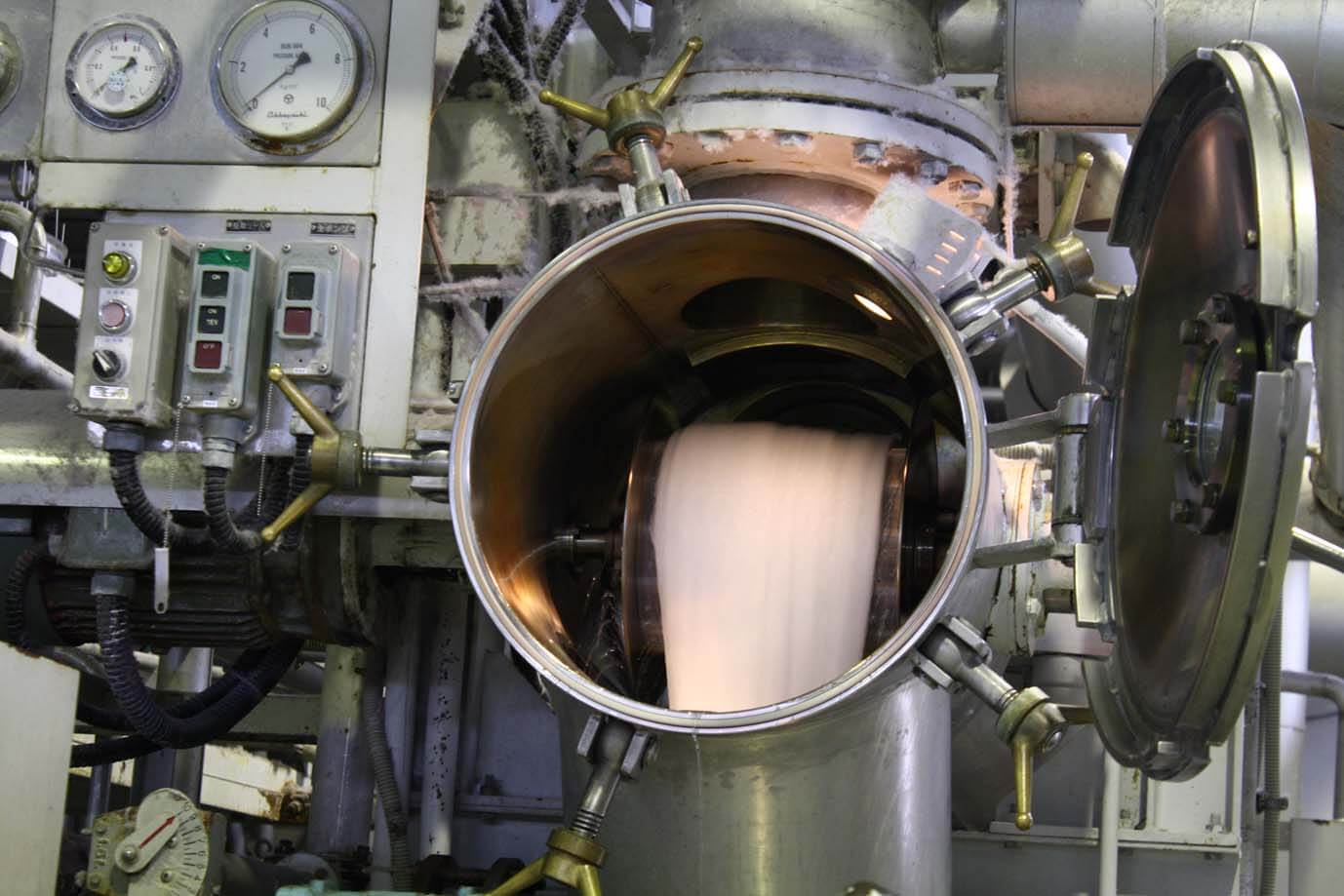

A large amount of water is essential for towel production. Before the yarn is made into finished towels, it is coated with glue to ensure weaving performance, which is then washed away with large amounts of water anddyed before it is made into finished towels. The wastewater used for washing off the glue and dyeing can amount to 1,000 tons per day, so facilities are needed to treat such a large volume of wastewater.

IKEUCHI ORGANIC performs the final dyeing process at “INTERWORKS,” a dyeing factory located in Saijo City, Ehime Prefecture, where the wastewater is treated.

This facility was established in 1992 by seven towel-related companies in Imabari, including IKEUCHI ORGANIC (then Ikeuchi Towel Co., Ltd.), in order to produce towels made in Japan with a thorough focus on quality.

The Seto Inland Sea is subject to the “Setouchi Law (Seto Inland Sea Environmental Protection Special Measures Law),” the most stringent wastewater regulations in the world, and newly constructed wastewater treatment facilitiesare obliged tomeet these standards.

The plant’s purification facility, thus completed, was a huge building the size of an official Olympic swimming pool, with three stories above ground and two below. It has a daily wastewater treatment capacity of 2,000 tons. The wastewater is treated by bacteria over a long period of time. The wastewater from the facility is said to be “clearer than ocean water,” and has even been featured on TV news programs.The wastewater standard is mandated to be less than 15 PPM COD.

Why we use chemical dyes

IKEUCHI ORGANIC avoids the use of environmentally hazardous chemicals such as chlorine in bleaching, and uses dyes that do not contain heavy metals such as lead, copper, and mercury in dyeing. However, we do not intend to say that all chemical dyes are bad. Some chemical dyes contain substances that cause allergies, so we eliminate them.

I learned this idea from Leif Norgaard of Novotex, the first company in the world to successfully commercialize organic cotton. He taught us that “the safest thing to do is to use chemicals under tight control.”

IKEUCHI ORGANIC uses pure underground water from the Ishizuchi mountain range to wash off the glue, dye the towels, and then carefully wash the towels for 6hours.

To ensure that the fabrics are safe even when chemicals are used, the final products are tested by Oeko-Tex, a Swissinstitution with international authority and high reliability in textile safety. There are four levels of certification, with Class 1, the highest level, being “safe for infants to eat.” Our organic towels and bamboo towels have received this Class 1 endorsement.

We have received some criticism for using chemicals even though we claim to be organic. However, we believe that the decision to use the minimum amount of chemicals necessary for the quality andlongevity of our products is an appropriate one.

Towels are daily necessities that require not only excellent water absorbency andtexture but also durability. We want our customers to be able to use our products for as long as possible, and maintaining their longevity is itself a way to reduce the burden on the environment. We do not accept manufacturing that encourages customers to easily replace their products.

Article written by

イケウチオーガニック