タオルのお役立ちコラムやイケウチオーガニックの取り組みをご紹介いたします。

Fluctuation gives contour and will. Until the sauna towel is dyed indigo.

2025.05.09

Table of Contents

We accept reservations for a limited number of indigo-dyed sauna towels each month.

Each towel is carefully dyed by hand using a technique called “tennen aku hikotodate,” in which natural materials are fermented to produce the dye solution.

Aiya Terroir ” is the company that handles the indigo dyeing process.

Aiya Terroir handles the entire process of indigo dyeing, from indigo cultivation to the production of dye dye dye, all by hand.

How does Aiya Terroir grow indigo and dye sauna towels indigo?

We asked Kenta Fujii and Yuta Shimizu, Aiya Terroir’s indigo dyers, about their path.

The indigo color can only be expressed in this land.

Aiya Terroir is located in Yamano Town in the mountains of Fukuyama City, Hiroshima Prefecture.

It is a small town with a population of approximately 600 people and rich in nature.

Terroir is a wine term meaning “the characteristics or character of the land.

The soil, the water, the air, the history, the culture, and the people. History, culture, and people.

The climate of the land is a major factor in creating uniqueness in manufacturing.

Based on this idea, we at Aiya Terroir work with indigo every day so that we can confidently say that the indigo color that can be expressed only in that region is our own color.

The photo above shows indigo seedlings.

At Aiya Terroir, indigo seeds are sown in the field from March to April.

The seeds sprout in about a week and grow quickly.

We spend about a month growing the seedlings, loving them every day so that they become strong and sturdy.

The photo above shows an indigo field.

From April to June, the grown indigo seedlings are replanted in different fields.

About 40,000 seedlings are grown at Aino Terroir.

Two months after planting the seedlings, the indigo plants grow to a height of about knee-high.

The photo below shows the indigo just at harvest time.

The leaves of the growing indigo plant will be as large as the palm of your hand.

Eventually, the leaves grow so thick that the soil in the field is no longer visible.

Harvesting is then carried out from July to September, when the midsummer heat is harshest.

However, since the pigment of indigo is contained only in the leaves, after harvesting, the indigo is chopped into small pieces and the stems and leaves are sorted.

After sorting, the leaves are slowly dried in a plastic greenhouse.

As shown in the photo below, the leaves are turned over with a bamboo stick and exposed to the full rays of the sun to dry them evenly.

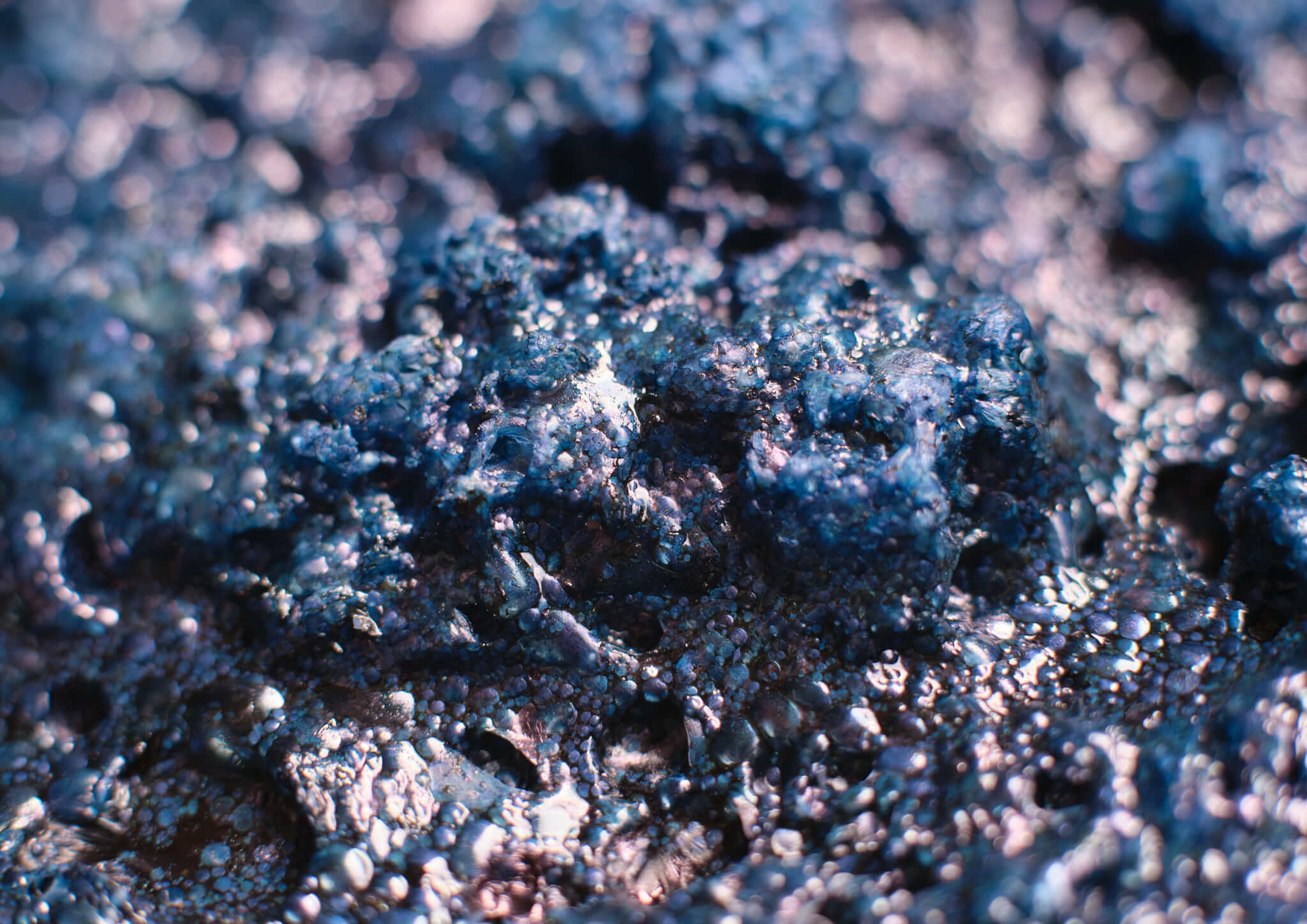

In October, the production of indigo dye, called dye dye made of dye leaves, begins.

Dried indigo leaves are piled in a pile and fermented while being given water and oxygen.

As the fermentation progresses, the center of the pile heats up to about 70 degrees Celsius, and at the same time, a strong smell of ammonia fills the air.

After about four months of fermentation, the dye is finally ready.

Indigo dyeing is something that deals with living creatures.

At Aiya Terroir, we dye indigo using the “natural lye fermentation technique.

This is one of the most traditional and time-consuming indigo dyeing techniques.

蒅(すくも)に、木灰を水に溶かして作った灰汁(あく)や、ふすま(小麦の外皮)などの天然素材を加え、自然発酵の力を借りて染液(せんえき)を育てていきます。

In the dye solution, microorganisms actively work to reduce the indigo pigment and prepare the fabric to fix a beautiful indigo color.

Kenta Fujii, the representative of Aiya Terroir, told us, “We dye with the help of microorganisms.

We dye indigo with the help of microorganisms. Microorganisms are living creatures, and just like humans, they get tired if they work too much, get in a bad mood if they are hungry, and become unfaithful if they don’t have a break (laughs).

So we have to save the amount of dyeing we do in a day. If you dye too much, it will be like working late into the night, and the condition of the dye will be ruined.

It is also important to give them two days a week off from dyeing to give them a rest. In addition, it is necessary to feed them rice by giving them bran or adding sake when they are not in good condition.

We need to create an environment that is like a super white company for the microorganisms (laughs). That is the most important thing to keep producing good indigo continuously.

In indigo dyeing, the object to be dyed is soaked in the dye solution and then exposed to air to oxidize it, resulting in a beautiful indigo color.

The object is soaked in the dye solution for 3 to 5 minutes, then pulled out, squeezed and spread out, and allowed to come into full contact with the air. By repeating this process, the color will be evenly and beautifully applied.

Since unevenness is more likely to occur if the dye is applied too infrequently, the dye is applied at least five times, even if it is to produce a light color.

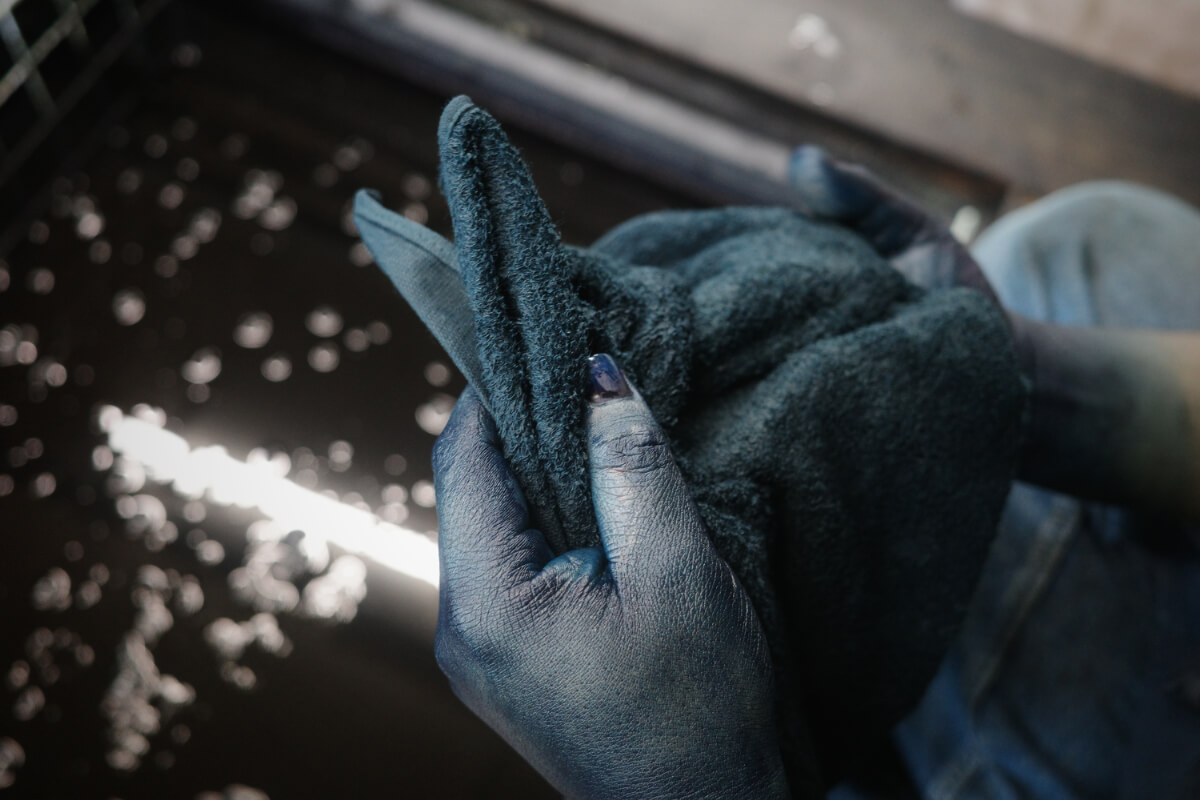

Also, at Aiya Terroir, all indigo dyeing work is done with bare hands.

Because the color is produced by the action of microorganisms, the condition of the dye solution changes slightly from day to day. In order to feel the slight differences on their skin, they dye with their bare hands.

Therefore, Mr. Fujii’s and Ms. Shimizu’s hands are always dyed indigo.

The “fluctuation” of the indigo dyeing process gives the outline and the will to the product.

The more you use an indigo-dyed item, the more the color softens, settles, and deepens its flavor.

For most products, color fading tends to be viewed negatively. However, in the case of indigo dyeing, this is exactly what makes it tasteful.

It is not deterioration over time, but beautification over time.

We hope that over a long period of time, you will grow a beautiful indigo color that is unique to your piece.

It is with this wish in mind that the two staff members of Aiya Terroir face the challenge of indigo dyeing.

Finally, when asked what kind of future he would like to achieve with IKEUCHI ORGANIC, he replied, “We make our own dyes and do indigo dyeing, but we don’t actually make any ‘products’.

We make our own dyes and dye our towels with indigo, but we are not actually making a “thing.

There is an object, the towel, and only when we dip it in the dye solution does our color come out. Our indigo color cannot exist without the intervention of an “object.

Moreover, a towel is already complete as a towel without any modification by us. What is the point of going to the trouble of dyeing them with indigo? We think about this every day.

The indigo color produced by indigo dyeing is a “fluctuating” color.

Both the condition of the microorganisms and ourselves, the indigo dyers, continue to change day by day. Therefore, exactly the same color will never be produced again. They fluctuate somewhat subtly.

However, it is precisely because we live in an age of overflowing goods and information, where everything is becoming more and more homogenized, I believe that the “fluctuation” of the indigo color will bring out the outline of the object and give it a kind of will.

The “fluctuation” of indigo dyeing will bring out the contours of the object and give it a will.

With such a future in mind, we would like to continue to work with indigo dyeing.

Online talk event with two members of Aiya Terroir. The event is connected to the studio online and includes an actual indigo dyeing demonstration.

IKEUCHI ORGANIC writes about the thoughts behind the aizome sauna towels in the “Note” section.

You can reserve your towel here.

Article written by

イケウチオーガニック