IKEUCHI ORGANICの人

HUMAN

IKEUCHI ORGANICの人 について

IKEUCHI ORGANICでつくられるタオルなどのファブリック製品たち。それらの原材料となるオーガニックコットンや染色での安全性について私たちはホームページをはじめ、様々な媒体やストアイベントなどで周知を行ってきました。代表である池内計司もテレビ、雑誌、WEBなどのメディアを通じてその想いを伝えています。

この様なIKEUCHI ORGANICの取り組みを支持頂いているファンの方に、もっとIKEUCHI ORGANICの事を知ってもらいたい。そんな時、まだ皆様に伝えていない事があることに気づきました。

それはIKEUCHI ORGANICで働いているタオル職人などの人々でした。タオルが製品化され、皆様の手に届くまでには、企画、機織り職人、縫製、検品、生産管理、品質管理、販売など様々なスタッフが関わっています。

池内タオルからIKEUCHI ORGANICへ社名変更をして2023年3月で丸9年。オーガニックな製品を世に送り出し、2073年の創業120周年には食べられるタオルをつくるという目標に向かう、IKEUCHI ORGANICの姿をこの連載“ IKEUCHI ORGANICの人 ”でお届け致します。

IKEUCHI ORGANICの人 の声、ぜひ最後までご覧ください。

PICK UP

-

Vol.56

お店に足を運んだ感覚で、オンラインストアを利用いただきたい。

オンラインストアに寄せられるお客様のご要望やご相談に寄り添うカスタマーサポートや出荷管理を担う石川さんにお話を伺いました。

Web カスタマーサポート・出荷管理 石川

-

Vol.54

全てのひとに明かりや希望を感じてもらえる、そんな場所でありたい

セールスコンダクター兼ストアマネージャーとして両ストアの責任者をつとめる益田さんに、ストアが目指している姿について語ってもらいました。

セールスコンダクター/ストアマネージャー 益田

-

Vol.52

タオル選びを通して、お客さまの「好き」を一緒に探していきたい

東京ストア店長をつとめる福山さんに、IKEUCHI ORGANICとの出会いや、どんな想いをもって店頭に立っているのかを語ってもらいました。

東京ストア店長 福山

-

Vol.51

みんなが安心して働けるよう、バックオフィスとして支えたい

日々の細かい事務処理に加え、働きやすい環境づくりを裏から支えてくれている、総務・経理業務を担当の青木さんにお話を伺いました。

管理部 主任 青木

-

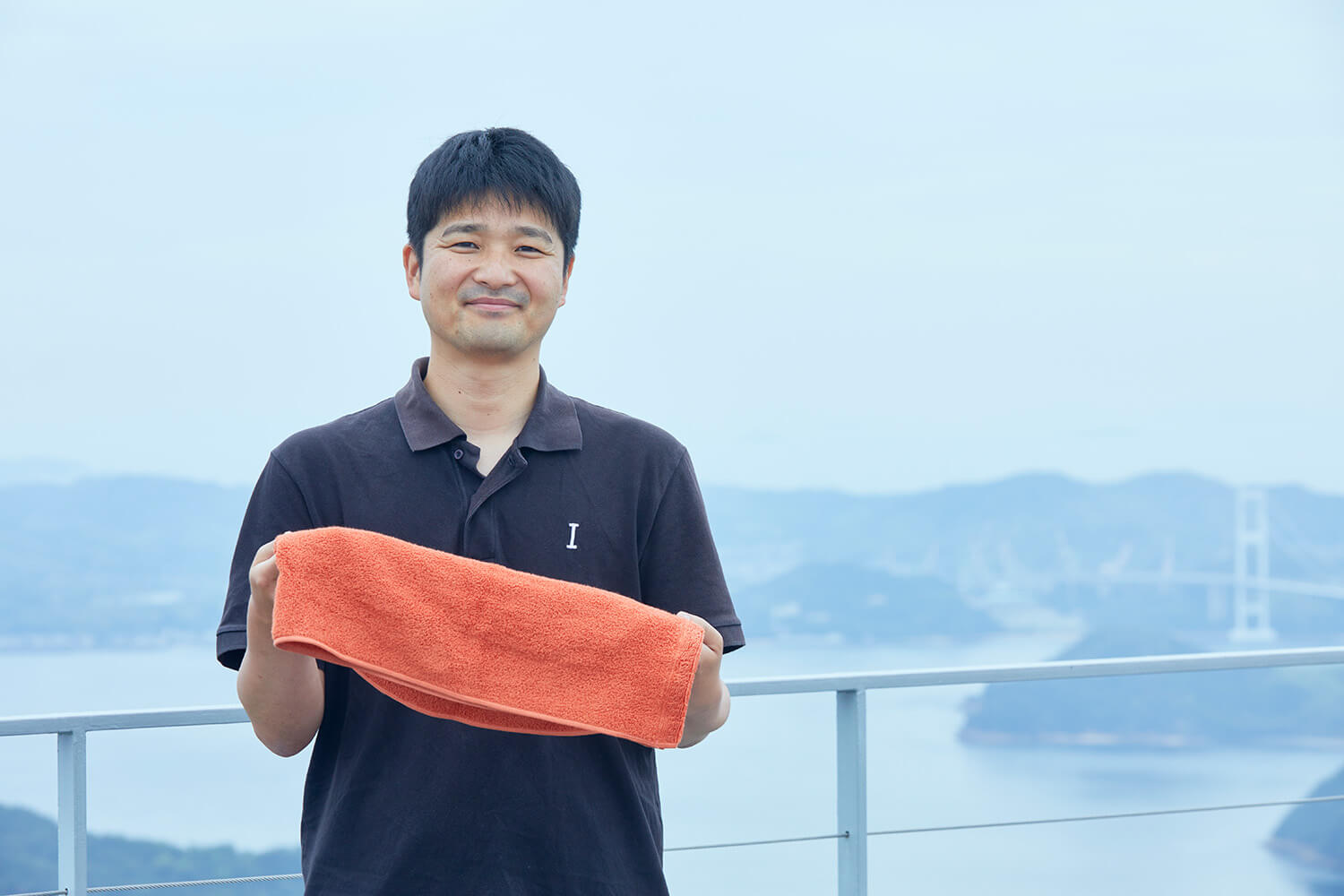

Vol.50

私たちの製品は食品という考えのもと、最大限の安全性を追求する

食品工場の安全基準である「ISO-22000」認証取得の陣頭指揮を取り、現在は管理責任者をつとめる曽我部さんにお話を伺いました。

業務推進室室長/ISO管理責任者 曽我部

-

Vol.56

お店に足を運んだ感覚で、オンラインストアを利用いただきたい。

オンラインストアに寄せられるお客様のご要望やご相談に寄り添うカスタマーサポートや出荷管理を担う石川さんにお話を伺いました。

Web カスタマーサポート・出荷管理 石川

-

Vol.54

全てのひとに明かりや希望を感じてもらえる、そんな場所でありたい

セールスコンダクター兼ストアマネージャーとして両ストアの責任者をつとめる益田さんに、ストアが目指している姿について語ってもらいました。

セールスコンダクター/ストアマネージャー 益田

-

Vol.52

タオル選びを通して、お客さまの「好き」を一緒に探していきたい

東京ストア店長をつとめる福山さんに、IKEUCHI ORGANICとの出会いや、どんな想いをもって店頭に立っているのかを語ってもらいました。

東京ストア店長 福山

-

Vol.51

みんなが安心して働けるよう、バックオフィスとして支えたい

日々の細かい事務処理に加え、働きやすい環境づくりを裏から支えてくれている、総務・経理業務を担当の青木さんにお話を伺いました。

管理部 主任 青木

-

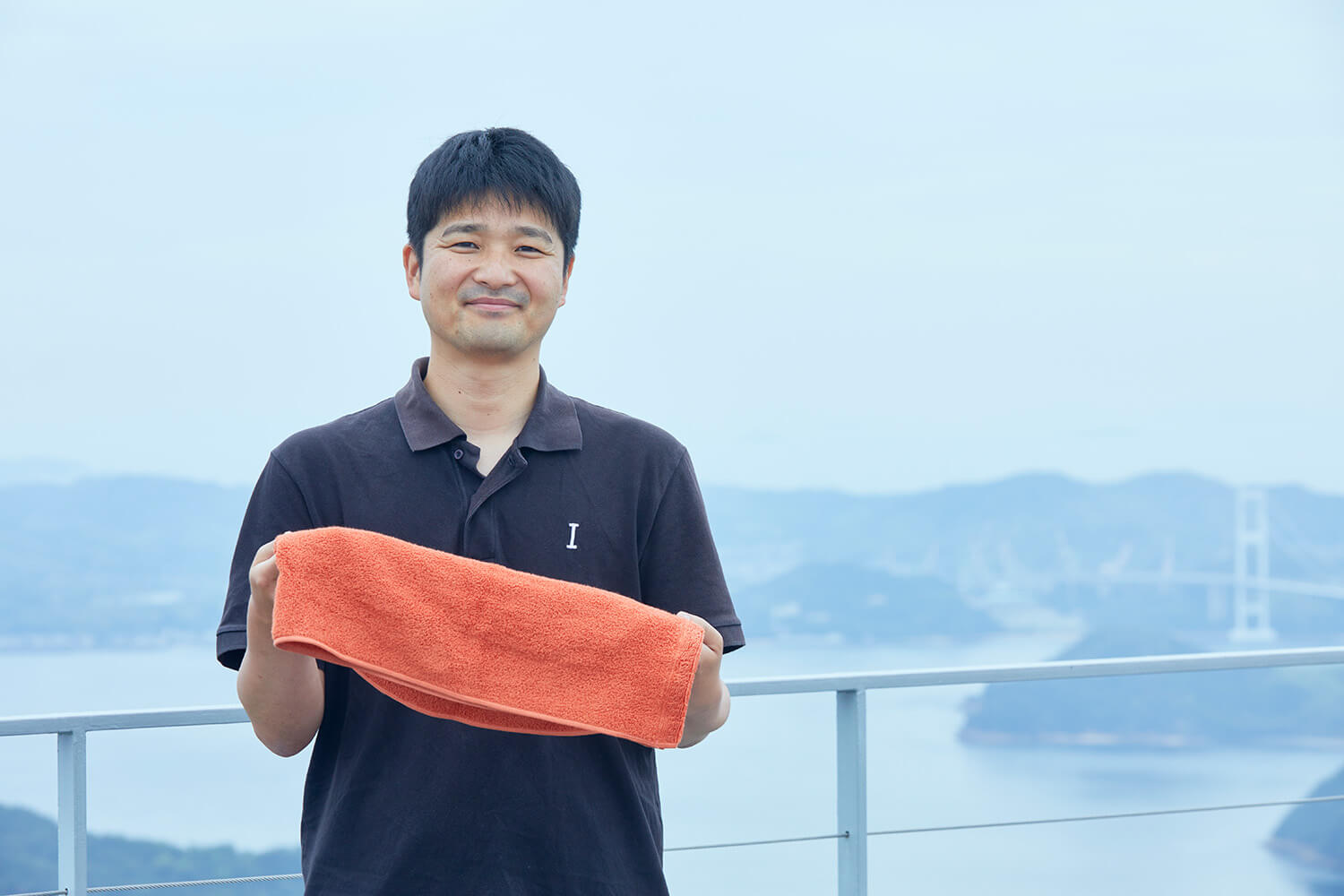

Vol.50

私たちの製品は食品という考えのもと、最大限の安全性を追求する

食品工場の安全基準である「ISO-22000」認証取得の陣頭指揮を取り、現在は管理責任者をつとめる曽我部さんにお話を伺いました。

業務推進室室長/ISO管理責任者 曽我部

-

Vol.49

検品という重要かつ大変な職場だからこそ、明るく元気に。

検品現場では、人の手と目を通して細かく確認し、品質を厳しく管理しています。明るく元気な白石さんに検品の仕事についてお話を伺いました。

検品・出荷・在庫管理 白石

-

Vol.48

オンラインの出荷担当として、一つひとつを丁寧にやっていく

商品の出荷対応や問い合わせ窓口など、オンラインストアの裏側を支えるスタッフとして10年以上働いてきた中山さんにお話を伺いました。

WEB 検品・出荷 中山

-

Vol.47

生産部長として目指す、みんなが前を向いて働ける環境づくり

ものづくりの全てを担う生産部。次々に起こる現場の問題に対応し、生産部の皆から信頼され、慕われている渡邉部長にお話を伺いました。

生産部 部長 渡邉

-

Vol.46

タオルの“設計”において、代表から学んだ譲れないポリシー

代表池内のイメージを設計に落とし込む「企画・設計」を担当している矢野さん。一筋縄ではいかない“設計”の仕事について、お話を伺いました。

製品開発・設計課長 矢野